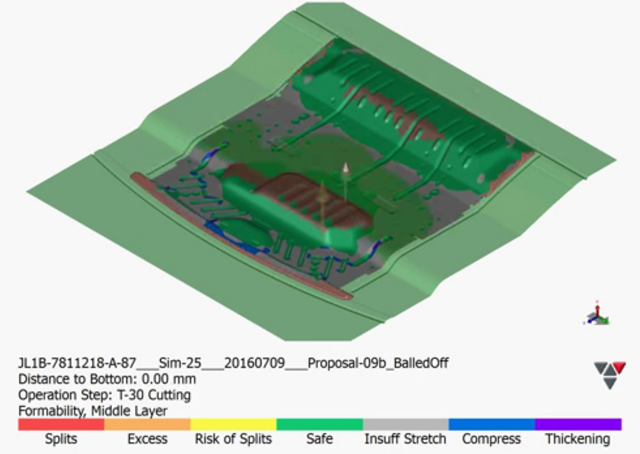

Simulation At CET, we offer a turn-key stamping and die simulation solution for your business. With our modern technology and software capabilities, we will perform simulations of your tooling designs and incorporate your materials to ensure an accurate assessment before beginning design and build. This process includes checking for a wide range of problem areas in a part before the die design and build begins. In doing so we can reduce tryout and start up times and create a quality die making a reliable and repeatable part. Our simulations can help identify issues including: Compression Thinning Splitting Formability Edge Strain Water Flow Analysis for Hot Stamp Thermal Analysis for Hot Stamp We continually update and improve our simulation model throughout the process to ensure that your final product will function properly in production in your operation. Our software capabilities for simulation include: 2 Seats of Autoform For Forming Simulation 1 Seat of PamStamp For Forming Simulation 1 seat…

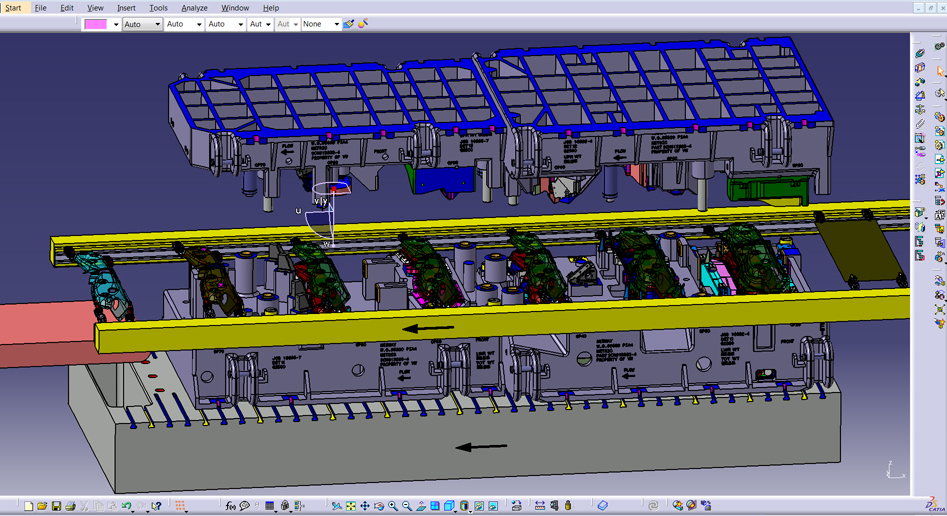

Design CET offers you a quality, turn-key solution to meet all of your custom die design needs. Our experienced CAD/CAM experts are experienced in designing a wide variety of custom dies including Hot Stamp, Tandem, Transfer, Progressive and Blank dies of almost any size you may require. We have designed dies for many of the biggest names in the automotive industry, and have a long history of providing quality, accurate die designs for a variety of customers. We will work with you at every step of the process from beginning to end to ensure accuracy of delivery, including determining materials and tooling, prototyping, part requirements, and more. Our CAD/CAM Design capabilities include: CAD Software: 20 Seats of Catia V5 Solid Modeling (HD2/MD2/KWA/QSR/GSO/DSE/STL/STP Configurations) 5 Seats of Siemens NX Ver. 9-11 1 Seat of Autocad 1 seat of VISI 2 seats of Solidworks CAM Software: 8 seats of 3 axis Powermill 3 seats of 5 axis Powermill 3 seats of Power Shape 2 seats of Vericut 2 seats of Lemoine…

Build At CET, we are expert builders of stamping dies for for our partners in the automotive as well as other industries. In conjunction with our design, simulation, and machining capabilities, we are able to build your part to your exact specifications. As your turnkey solution for all of your tool and die needs, CET will handle the entire build process in-house and to your requirements. Quality is at the centre of everything we do at CET, and we will work to give you the most accurate build you can get with the shortest turnaround time. Our laser capabilities allow us to quickly and accurately create a small run of parts to test, try out, and inspect them. This allows us to create a small run of your part to ensure it meets the highest quality standards before putting it into full production. CET can work with a wide range of materials in building your part in order to meet your needs, including dual-phase high strength steel. We do tooling for progressive, transfer, and line dies of almost…

Tryout After completing the build of your die, our tryout facilities allow us to ensure that it meets the highest standards of accuracy based on your needs. We will ensure that your dies meet all of your requirements before putting them into full production and delivery. Our tryout capabilities include presses of up to 4 000 tons and a 100 x 180 bed size. With our laser capabilities, we can put a small run of your part into production for trim and adjust a part and test it to quickly and precisely adjust it based on our tryout results. With our commitment to quality assurance, you can count on CET to get your die produced correctly down to the smallest measurements. Our tryout capabilities include: 1 4000 ton, Bed Size 184 x 108 x 65 , Shut Height 42 " Verson hydraulic Press upgraded and modified to simulate any velocity curve as per mechanical press. (3) 1000 Ton Danly Straight Sided Presses Size 180 x 96 x 84 SH, 36" Stroke 1 1000 Ton Bliss Straight Side Double Crank Press…

Inspection Quality Assurance is at the heart of everything we do. We go beyond providing just the fixture gauge readings for the parts we cut by providing our clients with CMM Reports from white light as well as blue light measurements. We want our customers to know that the parts we manufacture for them are going to fall within tolerance each and every time. White and Blue Light Inspection: We are equipped with White and Blue light scanning systems that allow us to take a more exact measurement of each part for maximum precision. Both white and blue light inspection takes an extremely accurate measurement, and can create a computer scan of your component down to the most exact detail. This technology allows you to see exactly where your parts inside and outside of tolerance from throughout their surface area, allowing for precise adjustments to be made before going into production. This state-of-the-art system gives you full part dimensional visualization for fast draw die development, and both…

CNC Machining & Laser Capabilities Canadian Engineering and Tool offers extensive high-speed CNC services in our facility, utilizing the most up-to-date software and machines to ensure the most accurate and high-quality final product for your business. Our CNC machines can handle jobs of almost any size and complexity, and we offer quick turnaround times on the machining of your components. These parts will be machined with your requirements, including size, materials, and tolerances, in mind throughout the process. Our High Speed CNC, Wire EDM and Laser Capabilities include: Parpas ML90 CNC (3+2) Boring Mill - 4M X 2M Parpas ML90 CNC (3+2) Boring Mill – 6M X 2.5M Starvision/Monforts Vertical Bridge Type CNC – 4.2M X 2.6M Starvision/Monforts Vertical Bridge Type CNC – 2.7M X 1.6M OKK 1250 Vertical CNC – 94” X 48” Rambaudi Vertical CNC – 118” X 49” Okuma Howa Vertical CNC – 80” X 30” Mazak I800 Variaxis Full 5 axis CNC – 800mm X 800mm Mazak 530C 3 axis CNC – 51” X 21” Okuma MC-60” X 59”VAE…