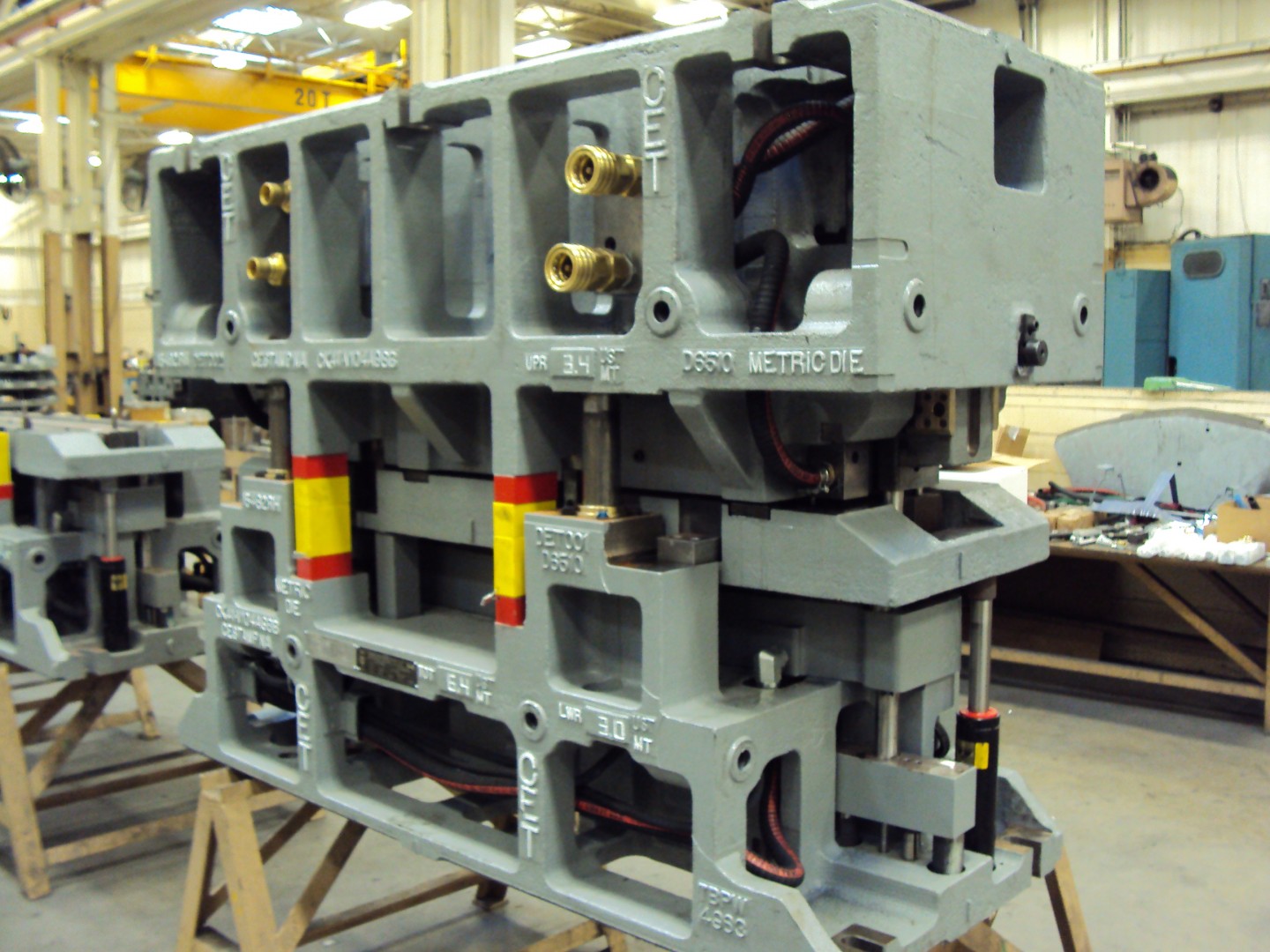

Hot Stamp Tooling Hot Stamp Tooling is the newest process in the automotive tooling industry, and at CET were are a leader in this. We were one of the earliest companies to implement hot stamp tooling in Southwestern Ontario because we could see all of the advantages that it provided us in meeting the needs of our automotive clients. Our extensive experience with this process has allowed us to develop a strong grasp on this new area for the tooling industry. Hot Stamp Tooling allows for the creation of high-strength, more intricate, and lighter-weight parts from a variety of materials. Parts that would require heavier pieces to be welded together when using cold stamping can now be created using one lighter piece through Hot Stamping. At CET, our hot stamping capabilities can handle dies of almost any size, from smaller, more intricate parts through to the largest components you need. This process also allows us to fall within very tight tolerances to meet your exact needs.

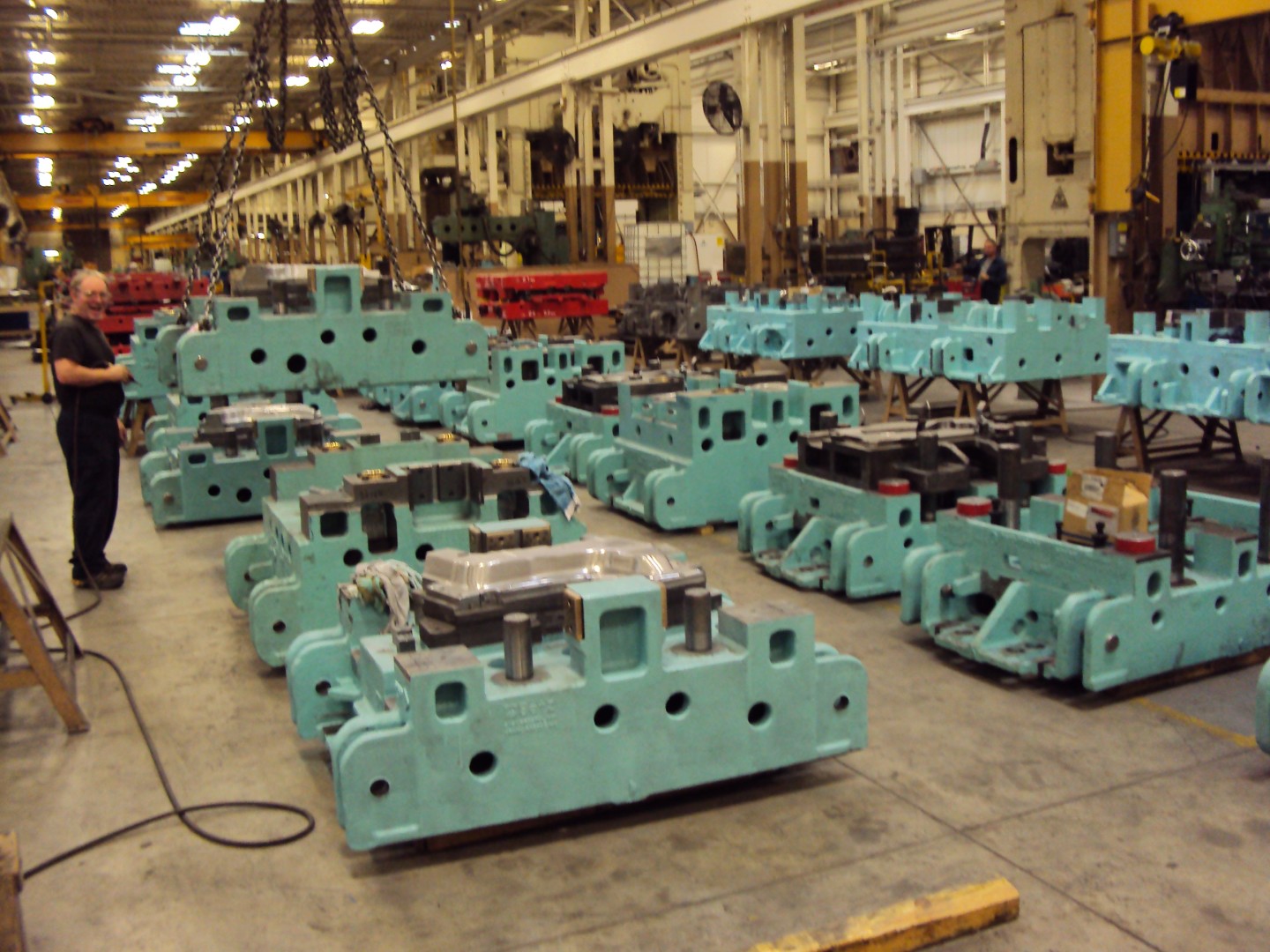

Cold Stamp Tooling We have extensive Cold Stamp Tooling capabilities to handle large parts and complete A & B component tooling. We can work with Dual Phase High-Strength Steel to stamp large components that are malleable, strong, and resistant to wear. As with our hot stamping process, our capabilities including manufacturing dies of almost any size you could need, from small components to very large ones. We offer a complete turnkey process for your cold stamp tooling needs, including Simulation, Design, Build, Tryout, White Light Inspection, and CMM inspection reports. CET has extensive experience in Cold Stamp Tooling, including work on a large array of automotive parts, progressive, line, and transfer tools for regular cold rolled steel as well as high-strength dual phase material. Throughout our process, you will experience our commitment to quality assurance at every step of the process. From beginning to end, CET will work to get your parts created within your exact tolerances and to your specifications. …